Ken Coster, www.vintagebmx.com: We actually started in 1963, located in Glendale. We started as a machine shop, and there was an airport across the street named "Skyway." At that time, Chuck Raudman thought, "ah, that's a cool name-Skyway," and that's how we got our name. The first products manufactured were for the aerospace industry, a lot of intricate parts for the aerospace-machine parts. Also Disney contacted Skyway, if you've ever seen the President Lincoln robot, a lot of those valves and intricate parts were made by Skyway Machine.

1979 Skyway catalog: During 1963, a small high-quality machine shop opened its doors in Van Nuys, California. Its founder, Chuck Raudman, was a journeyman machinist and began to establish a reputation for precision work in the aerospace industry. Tight tolerance work, which other machine shops would "no bid" because of its difficulty, found its way into the milling machines and lathes of this new operation. Ultimately, these parts were installed in many of the space program's missiles.

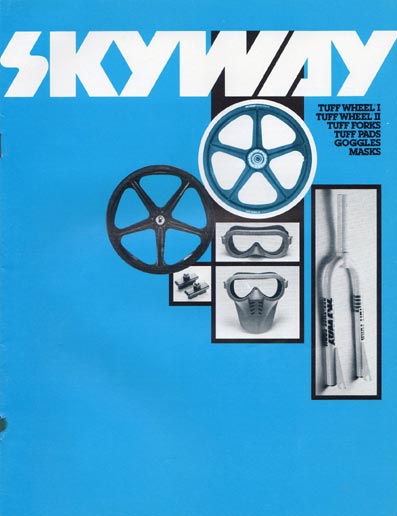

Tuff Wheels were the first 20" wheel to be molded in the world. Tuff Wheels are made of a proprietary blend of glass reinforced nylon.

1979 Skyway catalog: In 1974, a new sport began to emerge in Southern California -bicycle motocross (BMX). Skyway saw the possibility of making a contribution to this rapidly growing market in the form of a new product-a 20 inch nylon 'mag type" bicycle wheel. The initial objective was to make a high quality, lightweight, colorable product with a maximum level of durability.

Ken Coster, www.vintagebmx.com: At first we thought we'd make a nylon motorcycle wheel because the founder of the company was a motorcycle racer, and thought it would be pretty cool to have a composite wheel for a motorcycle. But talking with material suppliers like DuPont, there was a concern with the heat that would be generated with the speed of a motorcycle. So about that time, BMX was starting to make a little noise out there-kids racing bicycles. So we thought, well, if we can't do a motorcycle wheel, maybe we could do a bicycle wheel. No one's ever done one, and that's what kicked it off. The original design for the Tuff 1 took lot of R&D. We knew there had to be spokes in there, but we knew we didn't want to have a lot of spokes to have them look like a wagon wheel, so the odd number amount of spokes we thought looked better, so we came up with the design of five spokes, and it was perfect for a 20-inch because of the span between the spokes was almost perfect--so you know the larger the span, the weaker the point--so we thought well, that's a good way to start. And we all thought the 5-spoke looked good, and that's how that design came and there was, we helped develop a toughener with Dupont to get the wheels strong and tough and not cause any rim spreading-you know with X amount of BFI in the tire, and we popped the first one out in 1974. The first wheel was all black.

Bicross and Skate magazine may 1990: Skyway sort les jantes a béton en zytel étudiées pour résister aux chocs spécifiques et apporter une meilleure souplesse aux roues. La jante à bâtons a participé à donner une identité et un look spécifique aux bicross de freestyle.

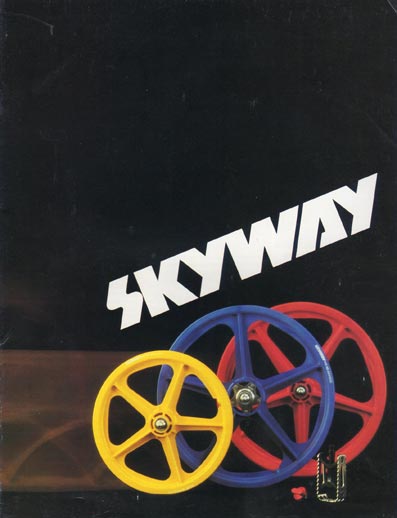

TUFF WHEELS IN COLORS.

Ken Coster, www.vintagebmx.com: The first color we came out with was in 1977, and it was, we were talking to Schwinn at that time, and they wanted yellow for their Scrambler model, they really liked the Tuff wheel concept. In fact, they were our first OEM customers. And then we also introduced red and blue

Ken Coster, www.vintagebmx.com: The Tuff Wheel II was introduced in '79, and we wanted the second generation to be lighter in weight. Basically that was the biggest issue, lighter in weight, which it did. And then we came up with the patented concept of the Kool hub, which you know, provided a heat-insulated air gap between the hub and the nylon wheel.

1979 Skyway catalog: In the Spring of 1979 came the commercial introduction of TUFF WHEEL II. The market readily accepted the new wheel. It was lighter in weight, and had even better impact resistance than the highly successful TUFF WHEEL® I.

The "Kool Hub" design made possible the insertion of other "unit hubs" such as the long requested free hub. At Skyway's request, Suntour created a free hub unit that was compatible with the TUFF WHEEL® II hub design. This gave customers the option of using either a coaster brake or a freewheel.

In conjunction with the development of a freewheel, Skyway began working with Kool Stop Manufacturing to develop a caliper brake pad which would "bite" on the low friction nylon surface of the TUFF WHEEL. After 9 months of development and testing, TUFF PADS were born. These pads, made of an exclusive proprietary composition, have been found to meet all Consumer Product Safety Commission requirements and are available in the standard red, yellow, blue and black TUFF WHEEL® II colors.

www.mauricemeyer.com: THE wheel of wheels. This is the big brother of the Tuff 1 used by many 70's Mongoose owners for racing and jumping radness. The Tuff 2 featured a new hub design and was offered with a variety of front hubs as the wheel evolved. It originally came with a narrow metal looseball hub, later it came with a wider alloy design with bearing races and eventually the plastic model shown here. Made of the Dupont Zytel plastic these wheels instantly transformed your racing bike into a sano styler. Available in coaster brake or freewheel with a rainbow of fruity colors to boot.

1979 Skyway catalog: 1979 also saw the installation of two new injection molding machines in the Redding facility. This $700,000 investment gives Skyway the maximum amount of flexibility in the manufacturing of its wheel products. It further indicates Skyway's continuing confidence in the strength and growth of the BMX market.

1979 Skyway catalog. (download)

TUFF WHEEL I 16' a 16 inch mini' version of Tuff Wheel I, was introduced at the winter trade shows.

TUFF PEDALS, extremely light graphite reinforced rebuildable pedals, made their debut in the summer. Also added were

TUFF PAD-Pro Model, an upgraded version of the original Tuff Pad, and

'BMX Racing Fever', an instructional book and cassette on all aspects of BMX.

SKYWAY TA FRAME AND FORK.

BMX Plus! december 1982: The official word from Skyway was that the company worked on the development of the frame for over one year. Initially; according to Craig Raudman of Skyway, once the decision was made to produce the T/A frame, it took quite a search to find someone to produce the unusual tear-drop shape they needed. After looking everywhere in the United States, Skyway finally turned to Japan, where they found two factories capable of producing the special chrome-moly tubes. The Ishiwata Seisakusho Co. Ltd. of Japan ultimately won the job, and we must say, the job they did was flawless. There were two ways to make the odd-shaped tubing. It could be drawn through a die in the desired shape or, as in the case of the Skyway tubing, it could be drawn round then shaped in a forming die. Once the tubing was dialed in, welding it all together in the right angles became the next step. The trick for Skyway was to figure out geometry that would work as well for the huge Andy Patterson as it would for the quick and nimble pro, Bob Medrano. According to Craig Raudman, countless hours of cutting and redesigning went into the prototypes. With the .geometry finally nailed down, Raudman hopped a plane for Japan to get the final manufacturing specs on the tubing settled. As of this writing, the frames are being completely produced in Japan. The forks are welded then shipped to this country, where Skyway gives them special treatment which involves annealing, re-heat treating, and plating. According to Craig, this is done in order to assure and verify that the fork is up to spec.

BMX Action january 1984: It's obvious from first glance that they invested tons of time and effort putting together the T/A frame and fork (T/A stands for Totally Aerodynamic). Completely 4130 chrome-moly, the frame and fork are things of beauty - almost masterpieces. Let's start at the back of the frame and work our way forward. The rear dropouts are not your basic snooze-a-roonie variety. They're die-cut into a very distinctive shape, knurled on the outside to give the axle nuts somethin' extra to grab onto, and they have a zoot tookin' hole punched out above the axle slot to add a little extra class. The seat and chain stays are tapered, teardrop-shaped tubes that go through a manufacturing process that makes the wall thickness of the material thicker where the taper is narrow, and thinner where the taper is wide. The bottom ends of these tubes are slotted to accept the dropouts, and then the ends are completely closed and welded on both sides of each dropout. The welding throughout the frame and fork is first-rate! Totally clean beads with apparently good penetration. Definitely some of the nicest we've seen in a long time. The seat tube is round at the top, and then below the clamping area it is expanded into a teardrop shape. Ultra-trick. The top and down tubes use 1 1/2 inch teardrop-shaped material. The four inch head tube is milled on the inside to provide the cups a perfect fit. By now, you're probably wondering about the frame weight. Well, it tipped the outstandingly accurate Mighty BMXA scales at 4 pounds. 2 ounces. Purty light. Okay, let's scrutinize the fork. The legs are made of 1 1/8 inch teardrop tubing, and the bottoms have been cleanly cut, formed, and welded shut. Very send. The dropouts are styled similar to the rear dropouts, all the way down to the tightening hole and the knurling for extra axle nut gription. The collar is drilled for a front brake. One of Skyway's goats for the forks was to make them light, and at 1 pound, 8 1/2 ounces, they did it. But they also wanted them to be able to take extreme punishment. So they went a big step beyond average manufacturing processes by completely heat-treating them after welding to between 30 and 36 on the Rockwell hardness scale. What this means is that these forks are tough! Since parts are subjected to very high temperatures during the heattreating process, they tend to warp. But Skyway puts their forks into special jigs to make sure they don't lose their shape. After they come out of the oven, the forks are carefully examined to make absolutely sure they're straight. The wheelbase is adjustable from 35 3/4 to 37 inches, so it should fit radsters 14 and over very nicely. Now that you have the full scoop, do ya wanna take a stab at the sticker price of all this. Forget it, we'll tell ya. 180 dockets. That even includes a Skyway California Lite frame pad. Pretty cool price for the goal involved.

1982 Skyway catalog. (download)

Skyway TA.

The total highlight of '85 was the colors that popped up. CW made an exclusive deal with Skyway to make lavender Tuffs, which were soon followed by light green, orange, pink, etc... This was definitely a bright year!

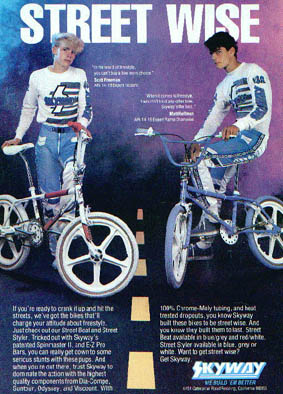

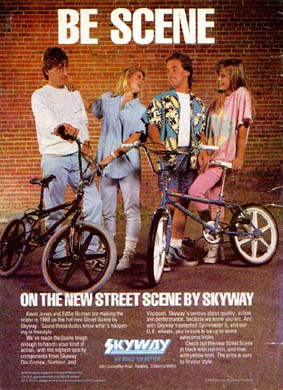

SKYWAY STREET BEAT.

Ad in BMX Action september 1985: Forget the ordinary with Street Beat, Skyway's new full-on freestyle machine. It's light enough to grab max air, and strong enough to beat the street. With heat-treated fork and rear drop-outs made from 100% 4130 chrome-moly, Street Beat's available in white, green and orange (frame and fork set only).

Freestyle BMX UK may 1985: Skyway have announced a new frameset designed specifically for freestyle. Of course everyone knows the T.A has been used for freestyle for eons and very good it is too, so what's different about the new frame ? Well for starters the T.A's 'totally aerodynamic' tubing has been abandoned in favour of ultra trick new squared off scaffolding on the top tube for easy framestands and strengh. Not only that, but the top tube also gets wider where it meets the headtube.

SKYWAY AXLE PEGS.

Ad in BMX Action september 1985: Freestyle Axle Pegs now come in 3/8''x 24 thread as well as 3/8"x 26.

SKYWAY PROMOTIONAL VIDEO.

Promotional video made by Unreel Productions (made KOS videos) for Skyway. Most of the footage is from 1985 San Diego AFA contest and some Del Mar footage of Hugo Gonzalez spinning a 360 over the fence. Footage includes Hugo Gonzalez, Dave Vanderspek, Robert Peterson, Scotty Freeman and Maurice Meyer with a cameo of Bob Haro riding a wheelie.

SKYWAY SPIN MASTER.

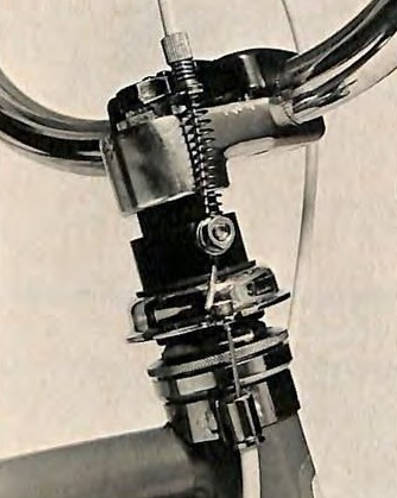

Freestylin november 1985: Not to be outdone, Skyway has come up with a trick and clean rear mod of its own. It works on the same principle as most of the others — the rear cable attaches to the stem-mounted mechanism, which moves up and down when the brakes are activated or released. It works. COLORS: Chrome. COST: $31.95.

Rotor Skyway 1985

Street Beat.

Skyway 1987 Spinmaster II.

Skyway has made some big cuts to their freestyle budget. They've eliminated all retainers salaries, entry fees and travel expenses for their riders. Their riders can still get product, but the cash flow is over, and team manager Jon Peterson has left the company.

www.expn.com, may 2002: Mat Hoffman and Simon Tabron are both riding Skyway Tuff Wheels. And they've both had wheel-shattering crashes recently.

Mike Dominguez 1983

Scott Freeman .... - spring 1988 remercié pour cause de grasse matinée le matin d'un contest.

Hugo Gonzales Hugo: I got picked up by Skyway after a contest in San Diego. They asked me if I was interested in the team and I said yes.

Ron Haro team manager .... - spring 1988

Mat Hoffman first sponsor; june 1986 - spring 1988 and then riding for Haro.

Kevin Jones 1987 - 1988

Maurice Meyer

Robert Peterson 1984 - 1986 Robert: Schwinn made me a great offer that I couldn't refuse.

Eddie Roman 1985 - 1988

Steve Swope 1988 - ....

Dave Vanderspek

Autumn 1988 Skyway aurait licencié l'intégralité de son team sans le remplacer. Plus de team officiel Skyway donc.

Mat Hoffman and Scott Freeman

Kevin Jones and Eddie Roman